After the 19th century, technological advancement has begun. Laser beam technology is one of them. “ CNC Laser cutter ” is our main focus in this article. We will discuss each of the working principles. In the later part of the article, we will explain the parts and mechanism of the laser cutting.

We all are familiar with the Laser. It is a device that emits light. It amplifies the view through the simulation of electromagnetic radiation. We can create the Laser from electrical discharges or lamps within a closed container. We can also use crystals to generate laser beams because their intensity is higher than the lasers from the electrical discharge. Hence, different types of laser cutters come. Moreover, a laser beam cutting is a technology that cuts metals into a various slice.

What is a CNC Laser Cutter?

Computer numeric control or CNC is a process of machining by Computer. Usually, we can perform many machine operations using computerized technology—for example, lathe cutting, milling, drilling, 3D cutting, shaping, etc.

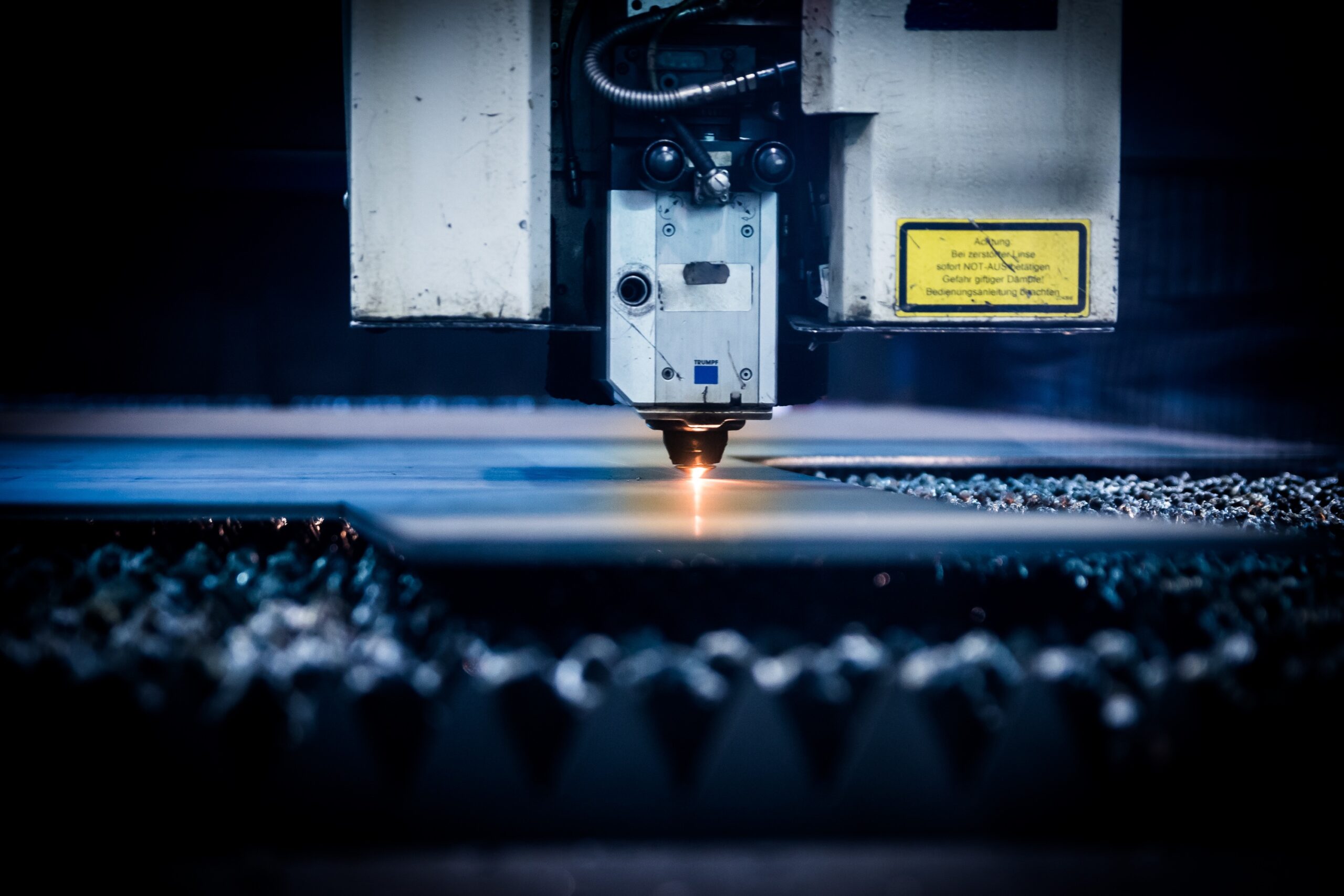

How does a laser cutter work?

We can define a CNC laser cutter as it is a process of laser cutting service using computerized technology. Just like the other CNC cutting machine. CNC laser engraver also cuts metals, woods, acrylic, paper, and so on. But the only difference is in their cutting tool.

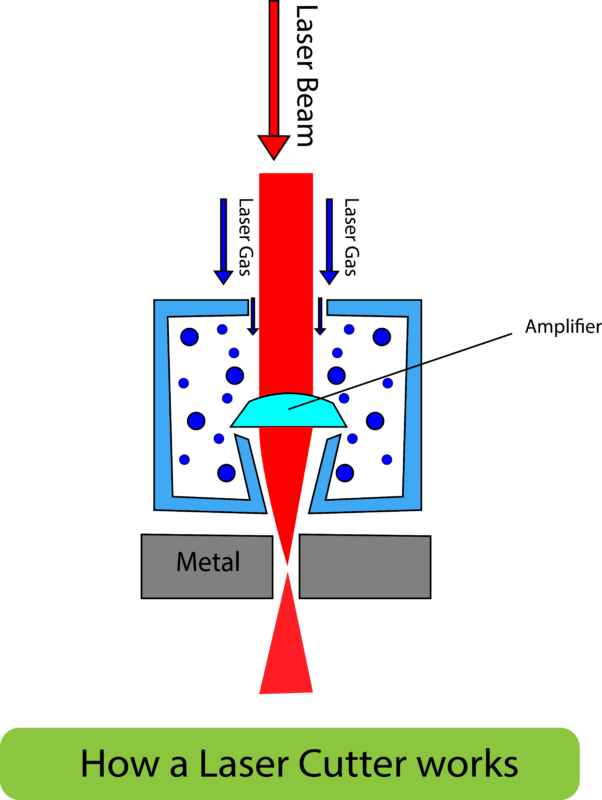

We all know that a laser is a device where a laser beam creates through electromagnetic radiation. Let’s see a summary of the working principle of a laser. First, the radiated beam directly falls on the amplification tool. We can use a mirror to reflect our beam if our laser device situated in some other locations.

And then there is a container into the beam will pass through. In that container, we will use some laser gasses. Finally, the laser beam, along with the gas, falls on the metal surface. The place quickly melts down after getting a laser beam onto it. Other than CO₂ gas, we can use other gasses like nitrogen, helium, xenon, and hydrogen, etc.

Working Principle of a CNC Laser cutter

CNC laser cutter has no difference with the other CNC cutting machine. Their working principle is almost the same as each other.

CNC laser cutting machine has a laser cutting tool. On the other CNC machine have a different cutting tool like plasma cutter or the router or others. But, all of them have a computer to operate the machining system. It is known as CNC or Computer Numeric Control. Let’s focus on the CNC laser engraver machine.

First, the Computer saves the command of the places we need to cut. After that, it converts the commands into the CNC machine language. The device now knows where to cut. It commands the motors to run precisely at the fixed frequency. The ball screw helps to transfer the rotational motion into the linear motion.

And then, the laser cutting tool comes to the exact position, and it starts cutting. Following the command from the Computer, it cuts accordingly on the correct places we need to cut.

CNC Laser engraving materials

About 90% of the factories in the world use this laser cutting machine. How? Most of the products have a date, and the company code printed on the product. Most of the plastic and metal industries use a laser engraver to print the date and codes. Besides, the laser cutter also cuts the thick sheets to make packaging. So, we have seen that the laser cutter can cut metals, plastics, glasses, acrylics, woods, etc.

Application of CNC Laser Cutter

Laser cutting is one of the most widely used manufacturing processes in the world. We will find laser cutting in industries such as the aeroscope, automotive, electronics, semiconductor, and medical sectors. There is a list of applications we will find for Laser cutting processes. For example,

- CNC laser cutting of metal.

- Laser surgery

- Laser cutting for marking and engraving

- Using laser cutting for packaging

- Ceramics CNC laser cutting.

- Cut off other non-metals.

Types of CNC Laser Cutter

The laser cutting box of the CNC laser cutter can be different in types based on the different working principles. Consequently, depending on the various structure of the laser cutting tool, we can classify it into three main types. They are,

- CNC Gas / CO₂ Laser Cutter: We have already mentioned above that the laser beam amplifies into the lens and then mix with the gasses. After that, it falls on the object surface and quickly melts that down. Therefore, the gas we will use in the container can be various in types such as nitrogen, helium, xenon, and hydrogen, etc. But the CO₂ gas is the most commonly used gas among all the gases. Besides, the CNC CO₂ laser cutter is also the most commonly used machine.

- CNC crystal Laser Cutter: We know that the Laser comes from the electrical discharge or lamps within a closed container. What if we use crystal here? Yes, we can. The crystals can give us high powered cutting. Crystal laser cutting is a process that uses lasers made from the crystals. The crystals are YAG (neodymium-doped yttrium aluminium garnet) and YVO (neodymium-doped yttrium ortho-vanadate).

- CNC Fiber Laser Cutter: In this type of the CNC laser cutter, we can use optical fibre cable to transfer the laser beam. The most critical benefit of this kind is, it can cut multiple cutting at the same time.

Based on the cutting materials

We already mentioned above at the application section that a CNC laser engraver can cut various materials. But their cutting machine is not similar. So, Depending on the cutting materials, we can classify them into the following categories.

- CNC metal laser cutter: This type of CNC laser cutter can cut metals like aluminium, copper, stainless steel, iron plate, carbon, sheet metal, etc. Metal has high-stress force, so cutting metals needs high intensity of the laser beams. For example, Laser cutter from Shandong Qintang Laser automation equipment, Laser Cutting Machine 1500w Price/CNC Fiber Laser Cutter Sheet Metal from Shandong Ruijie CNC technology group Co. Ltd., etc.

- Glass engraving CNC Laser Cutter: Glass engraving machine can generally cut the not-metallic object such as glass, wood, and others. We know that the glass is highly fragile. So, while engraving a CNC glass engraving machine, rely on the high engraving speed, high efficiency, and good engraving quality. For example Glass engraver from Jinan Jindiao technology, Co. Ltd.,

- CNC laser woodcutter: This type of machine generally woodcutting. It also processes wood, Acrylic, PBS, ceramic, leather, textile, paper products, plastic, metal, bamboo, glass, and other non-metallic materials. For example, Building Material Shops Laser Cutter, CNC Wood 1390 Laser Cutting Machine LP Laser Hot Co2 Laser Cutter Cnc Wood Acrylic 1390 Laser Cutting Machine from Shandong Leapion Machinery Co., Ltd.

Based on the Dimensional cutting

Can we make a sculpture using all the laser cutter? No, right? We need some extra features to get that. SO, depending on the dimensional cutting, we can further divide the laser cutter into the main two types. They are,

- 2D laser cutter CNC: This type of CNC machine can move all three axes. They can cut two-dimensional cutting. All of the examples we mentioned are the example of two-dimensional cutting.

- 3D laser cutter CNC: Other than three-axis, this type of CNC laser cutter can rotate. Therefore, it can make three-dimensional cutting. For example, 1390 Cnc Nonmetal Co2 3d Laser Cutter Engraver for Bottle Glass Paper Plywood Acrylic is from Jinan Yaoneng Machinery Technology Co., Ltd.

The basic structure of the CNC Laser Cutter

A CNC laser cutter consists of different parts and mechanism. First, we can define the parts and mechanism into two primary division. One is the digital mechanism, and the other one is the mechanical mechanism.

- The digital mechanism consists of the Computer and the CNC machine operator. We generally give our design to the Computer, and then Computer passes the design to the CNC machine. And this the CNC machine get its design in its language. Now its time to give the commands to the mechanical parts.

- Mechanical parts consist of many different kinds of mechanism. For example, the main working table and its parts, the laser cutting tool, wiring systems, etc. are the essential parts. Based on the several parts of them, we can further divide the mechanical parts into two primary division. One is the main working table, and one is the laser cutting tool.

The main working mechanism

The working table can be both portable and fixed. Portable CNC laser cutter can change place when it is necessary. On the other side, the fixed working table can not change place. If can then it needs lots of joints to assemble. If the changing place matters, we suggest choosing the portable CNC laser engraver.

However, The working table has three axes guideline. There are three motors attached to the ball screws. We give the pulse signal number to the motor, and motor place the position of the cutting tool to the desired position.

Laser Cutting Tool

Let’s see the laser cutting picture again. WE can see the Laser is coming from a source. That source can be an electrical discharge or lamp radiated Laser, or it can be a Laser from crystal radiated Laser. After that, the Laser travels a distance to reach the lens. The travelling way can be an optical fibre or others depending on the types of the CNC laser cutter.

After the lens, we will find a laser container box. The container contains the gas particles—for example, CO₂, nitrogen, etc. Subsequently, the laser beam contacts with the gas-particle and directly hits the surface of the object. It quickly melts down the object materials at that specific place. Finally, we get the object in our desired shape.

How to choose a CNC Laser cutter

- Laser beam intensity: Metal needs high intensity, then wood, the plastic, and then so on. So, the laser beam intensity is essential to look at before we choose.

- Cutting Accuracy: We all know that the beauty lies on the accuracy. The more the accurate is, the more the best design is. We must focus on the laser accuracy too.

- Safety qualities: The beam is a kind of light particle. So, it will reflect on the place surface. Consequently, safety is a priority.

Advantages

- Laser cutting does not require the changing of the tool. Therefore, it is flexible than the other cutting tool.

- The primary advantage of laser cutting is accuracy. It gives the most accurate cutting than the other CNC cutting operation.

- Laser cutting is faster than the other traditional cutting.

- CNC laser cutter is an automated cutting process.

- It gives us a better quality product.

- The operator does not require to change anything. Therefore, it’s a contactless operation

- The different machines are versatile to different materials.

Disadvantages

- The operator must be experienced enough to operate this laser cutter.

- The cutting intensity depends on the thickness of the metal. So, we must define before we go for the cutting.

- CNC laser cutter is more expensive than the other automated cutting machine.

Precaution

- The instructor must be present while operating the machine.

- Never leave the machine unattended.

- The instructor must select the object.

- Wear safety glasses.

- Clean up the debris.

- Identify the fire extinguisher before the machining.

Maintenance

- After the operation, we must clean up the machine.

- We should put the tool where it was.

- We must not leave the machine unattended.

Summary

After all, we have understood the basic working principle of the CNC laser cutter. Furthermore, we also discussed the basic structure of the machine. Besides, we have also discussed the laser cutting working principle and its structure. Lastly, we have illustrated the advantages and disadvantages of laser cutting. And at last, we must double-check the precaution and the maintenance part.

Therefore, we hope we could make your research easier. Suppose you are interested in the other CNC machining. Please visit the lick attested with the CNC machining. Keep reading our guidelines, and we will always be by your side with the best explanations of the machines. So, keep it updated and best of luck on your projects.