Wood is one of the most famous materials on earth. Before the 1950s, wood artists used their hands to demonstrate architecture. So, we know it took lots of time to finish. But, the CNC wood machines made that easy for us. In this article, we will discuss the CNC wood router machine and its types and applications.

A Computer Numerical Control or CNC router machine is an automated cutting machine. This machine is faster than hand-held cutting. Usually, materials like wood, aluminum, composites, steel, plastic, glass, and foams are the materials for this machine.

There are some types of CNC router machines. Among them, the CNC wood router is the one.

What is a CNC wood Router?

CNC wood router is an automated machine that cuts the object to some desired shape. This computer-controlled machine process the wooden materials depending on the design given by the operator. Moreover, This device is handy for both the wood industry and workshops.

Working Process

The working process of this machine is straightforward. Firstly, we draw our design on CAD (Computer-Aided Design) Softwares. For example, Rhino3D, AutoCAD, SolidWorks, SketchList3D are noteworthy. Secondly, we convert the CAD design into the CNC machine language. In this case, we can use Mach3, Nc-studio, Syntec, DSP, Siemens software for CNC control.

Thirdly, we put our object on the table. Subsequently, we must tighten the screw to fix the target object with the bench rigidly. Finally, we carefully start the machine. It will automatically finish its job. So, we can go to the café and enjoy some snacks at that time.

Working Principle

A CNC wood router can be of various types. We will briefly discuss them in the kind of CNC router section. In this part, we will have a glance at the working principle of the 3-axis CNC wood router machine.

The cutting tool has a motor that can move on the z-axis. It means the cutting tool can go up and down. On the other side, The cutting tool and the engine are situated inside a box that can move only on Y-axis. At last, the total parts mentioned above can run along the X-axis. Consequently, we call this machine a three-axis router.

Following the codes from the operating software, these three motors run accordingly. But before it starts to the operation, it goes back to the origin and begins from there.

Materials

Does a CNC router cut only woods? The answer is NO. It can cut only hard materials like wood. Apart from this, a CNC wood router can not cut metal because the strength of the CNC wood router is not enough for the metals. However, a CNC router can drill not only the woods but also acrylic, PVC ( Polyvinyl chloride) board, Double-color board, MDF (Medium-density Fiber), Marble, Fireboard, Rubber board, Glass, Crystals, etc.

Application of CNC Router

CNC router for woodworking has a broad side of the application. We use these tools every day. Starting from the furniture to the signboard, all are very useful. Let’s see some applications in which we use our CNC wood routing machine.

- Products and Manufacturing: Industries are using this machine to make wholesale products because the number of sales is enormous. The windows, doors, shelves, handy crafts, wall portraits, blocks, chairs, beds, etc. There are few brands in the market. They provide unique designs and architecture on their product.

- Decorations: We are very much familiar with wooden architecture. The banks, museums, even in school we will find some design on the wood. While sitting on the bench, we will see some letters written on the wood. CNC wood router can easily decorate these things.

- Musical instruments: We will design on the guitar, flutes, keyboards, harmonium, etc. We can easily create them on the CNC router machine.

- Furniture: Furniture is the most useful item in our daily life. The design on the chair leg, on the bedside, reading table, dining table, doors, windows, gates, flower vases, mugs all are the best example for the CNC router application.

- Others: Except for these applications, CNC router can also make the signboard design and different composite products.

Types of CNC wood routers

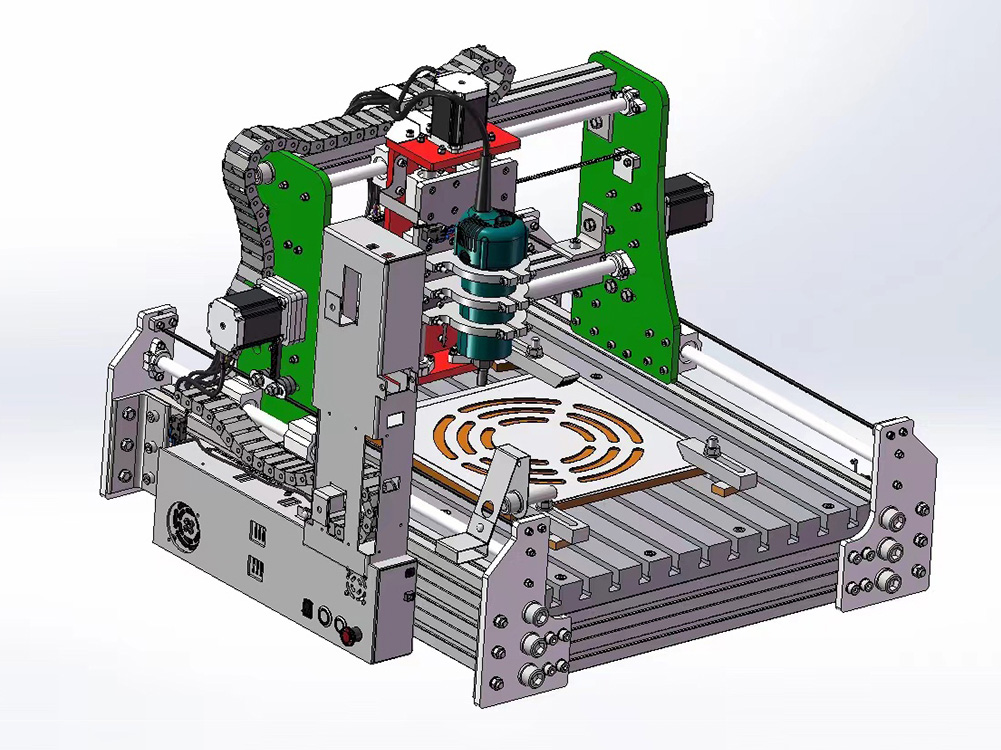

Routers usually have a mighty motor. It rotates the cutting tool to engrave inside the wood. We have already mentioned above that a CNC router machine can be various in types. They usually are divided into two groups—for example, CNC wood router machine and CNC mini wood router machine.

CNC wood router that is bigger than the mini routers works fine at the more prominent workshops and the industry. These wood routers typically have more than 1200 mm of length. The furniture like door, giant calligraphic board, round table, etc. are the best example. But, designing a smaller wood product is not convenient for these kinds of CNC wood routers.

On the other hand, CNC mini wood routers are smaller than the above routers. They are usually less than 1000 mm in length. Let’s say an example; the CNC router from Jinan Quick-fullteck CNC machines. It is a 600 x 900 mm mini wood router. It has 0.3 approx HP motor. The smaller signboard, writing letters on the board, short portraits, pictures, etc. are the best example that we can design using this mini wood router.

CNC wood routers based on the axis

CNC wood router machine has most commonly of 3 axes. But depending on the complexity of the design, the CNC wood router can further have three kinds. They are:

- 3-axis CNC routers: 3 axis CNC routers are most common in nature. The tool can move on the x-axis, Y-axis and Z-axis. 3-axis CNC router offers single or twin tables. The spindle can also be multiple. For example, Jinan Quick_Fullteck 6090 CNC router machine, Hot sale Multi Head Drilling Machine ATC CNC Router CNC Woodworking Engraving/Carving/Drilling Machine, are the best example of this type.

- 4-axis CNC routers: Weifang H&H International Corp., presenting a four-axis CNC router machine, can be our best example to explain. As we know, the 4-axis CNC router machine has higher precision than the 3-axis CNC router. But what are the axes here? Here, we will find three axes as usual XYZ-axis. In this type of machine, we will find another spindle at the end of the device. That’s the last axis we will discover from this machine.

- 5-axis CNC routers: This type of machine has the highest precision range. They are different from each of the devices mentioned above. Watch this YouTube Video. It will make you clear about the 5-axis of the routers.

CNC wood machine types based on working principle

Based on the working principle and structural difference, the CNC wood router machine further has four common types. They are,

- ATC CNC router: ATC stands for Automated tool changer. First and foremost, we know that one tool can not complete a design. Different types of the cutting tool have a separate cutting feature. In this type of routing machine, the device can automatically change the tool, which is necessary for the cutting. For example, 1224 1325 1530 2030 size ATC CNC router from Jinan Quick_fullteck CNC machines.

- Rotary CNC router: This type of routing machine is suitable for 2D/3D sculpture. For example, the Human body, Buddhist statue, 3D furniture projects, table legs, sofa legs, wooden columns, etc. The cutting tool can rotate around the target object. Also, it cuts the place where it is necessary. For example, Servo motor CNC router ele1836 with rotary spindle from Jinan Blue elephant CNC machines.

- Multi-head CNC router: The name reminds us that there are multiple heads on this type of machine. Right, this type of device has two or more cutting features at the same time. For example, Hot sale Multi Head Drilling Machine ATC CNC Router CNC Woodworking Engraving/Carving/Drilling Machine from Hefei Dilei Engraving Equipment.

- Multi-Spindle CNC wood router: This type of the CNC router machine, has multiple heads with the various spindle feature. The multiple-heads can operate different spindle directions at the same time—for example, CNC Router CNC Milling Machine with multi-spindle from Jinan Jinshike CNC Equipment.

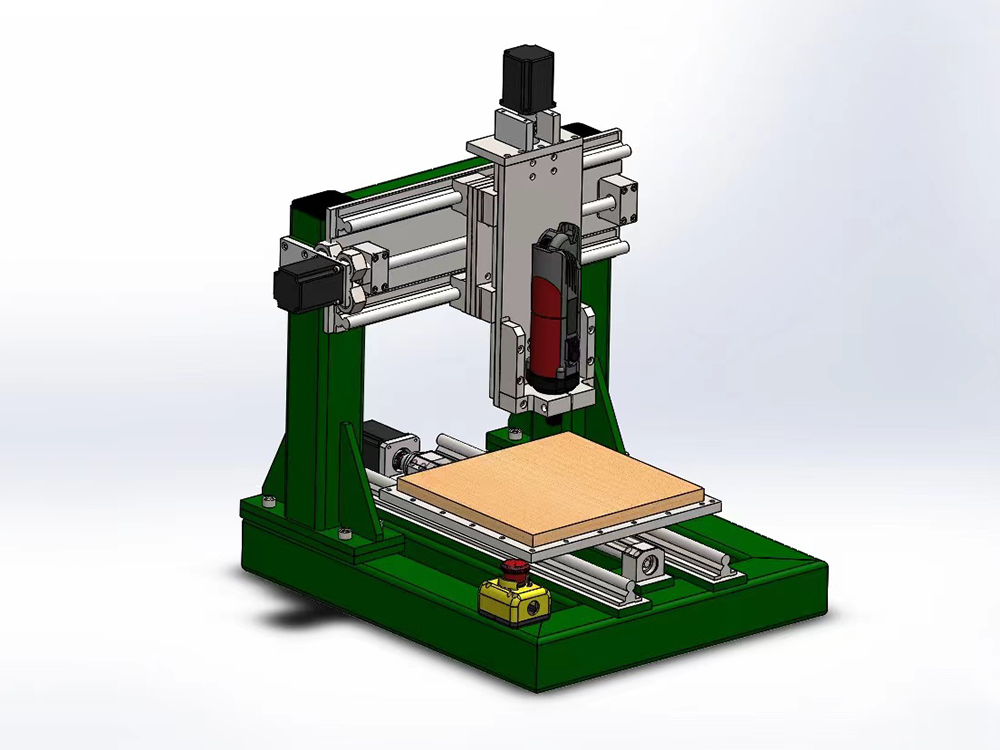

The basic structure of the CNC Wood routers

The structure of the CNC wood routers consists of many different consecutive parts. We will discuss the main components of the device.

First, there’s a basement. Based on this we can also classify the routers. They are Pin routers, Arm routers, mobile table routers.

The second, the moving axis guideline. There are three axes on the most common CNC routers. On this guideline, the motor lets the parts move along the axis.

The third component is the working table. On this table, the device cuts the targeted object. Fourth, the device has three stepper motors. These motors run the screws. As we know, the working principle of the ball circle motor that is it transfers the rotational motion into the linear motion. Based on this working principle, the CNC router also has three motors that move the rotational movement into the linear motion.

Fifth, most importantly, a router machine must have some cutting tools. CNC router can have different kinds of cutting tools. Based on different purposes, the devices change the cutting tool. Finally, we must need an operating device that can run the whole machine. Here, we convert the CAD design into the CNC language.

How to choose a CNC wood router machine?

Can we make all the wooden designs on the same routing device? Of course, No, right? The Particular Device can perform different jobs. For example, to make a digital drawing on the door, can we make it using the mini CNC router? No. Because the power is not enough to engrave such elements. So, we must follow some guidelines to ensure that our demands go with our desire. The following are a few vital factors that we must consider before we go for the choosing.

- Motor Power

- Size of the board

- Cutting tool kit

- Axes of guidelines

- Price

- Customer Reviews

Main advantages

Without a doubt, CNC routers brought us a great favor to finish our projects faster than before. Besides this benefit, there are three main advantages of using a CNC router. They are,

- Precision Cutting: Machine language is the most accurate. Human-held cutting surely will have defects. But a machine can not make mistakes. Therefore, precision cutting is the best advantage of the CNC routers.

- Different Materials: Using the CNC routers, we can process various materials other than wood. We have already mentioned the name of the materials.

- Flexibility and adaptability: Using a CNC router is more flexible because we can easily change the target object according to our desire. Besides, we can simply input the design on the computer and get our results on the machine.

- Decreases the Labor cost: Surely, to operate a CNC router no need for laborers because we can smoothly perform all the tasks without any help.

Precaution

- Read and understand the user manual before we go for the operation.

- Read and understand the CNC router machine safety manual.

- The experienced operator should run the machine to avoid mistakes.

- We don’t need to use the router machine other than the intended use.

- Wear safety glasses while using the CNC router.

- Keep our visitors safe.

- Not allow children to get inside the lab.

Maintenance

- Ensure cleanliness.

- Change the filters after the operation.

- Ensure the uses of the lubricant.

- Keep the air supply clean.

- Provide safe and proper electrical power.

Summary

We have tried to explain everything about the CNC routers above. CNC router can be our best friend if we can properly operate it. It’s the best thing to implement your art on your wood. As we knew above that, a CNC router is so sensitive to use. So, we must learn each and everything about the router machine before we go for the operation.

However, there are lots of CNC machines in the market, depending on the different purposes of use. We have well explained here about the general types of CNC machines. At last, we will strongly recommend having proper knowledge before you go to buy a CNC router.