CNC Machine is a machine with computer system which usually commands by the coded program to the physical machine for performing some cutting or shaping processes.

CNC stands for Computer Numerical Control. It came from NC- Numerical Control. From the 1940s the NC system has developed into a CNC system. In the 2020s, CNC is now one of the most used technology in the manufacturing aera. Hence, most of the industry uses different types onf CNC machines to cuts materials like metal, wood, plastic, acrylic, etc.

In this article, we will first have a glance at CNC language, and then we will go for the different types of CNC machines and their applications. We will see their working process on YouTube videos.

CNC Language

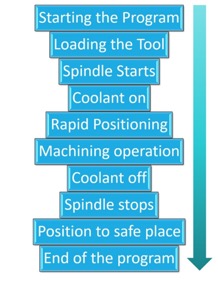

Before diving into types of CNC machines, let’s talk about the CNC language. CNC language is a group of programs that is normally operated from computer to perform some collective shaping processes without manual operation. CNC program doesn’t have any interrupt opportunities like other programming languages. It normally performs one by one from the serial coding. For most types of CNC machiens, Following are the serial steps of CNC Language: Starting the Program >> Loading the tool >> Spindle starts >> Coolant on >> Rapid Positioning >> Machining operation >> Coolant off >> Stop spindle >> Position to safe place >> Program ends.

The listed serial is the most straightforward notation on how a CNC machine works. In General, this language is not an actual computer programming language. There are variations in the code but no like what we think in computer science. It revolves around the tool to make specific shapes.

G and M code are the basic CNC building blocks. G-code is the universal programming language in the world for any computer numerical control (CNC) machines where M code is the underlying machine code which gives instructions when to turn on and off. CNC language is one of the simplest machine languages in the world. It is effortless to learn to operate most types of CNC machines. Later studies we will publish detail about this language and how we can run a CNC machine.

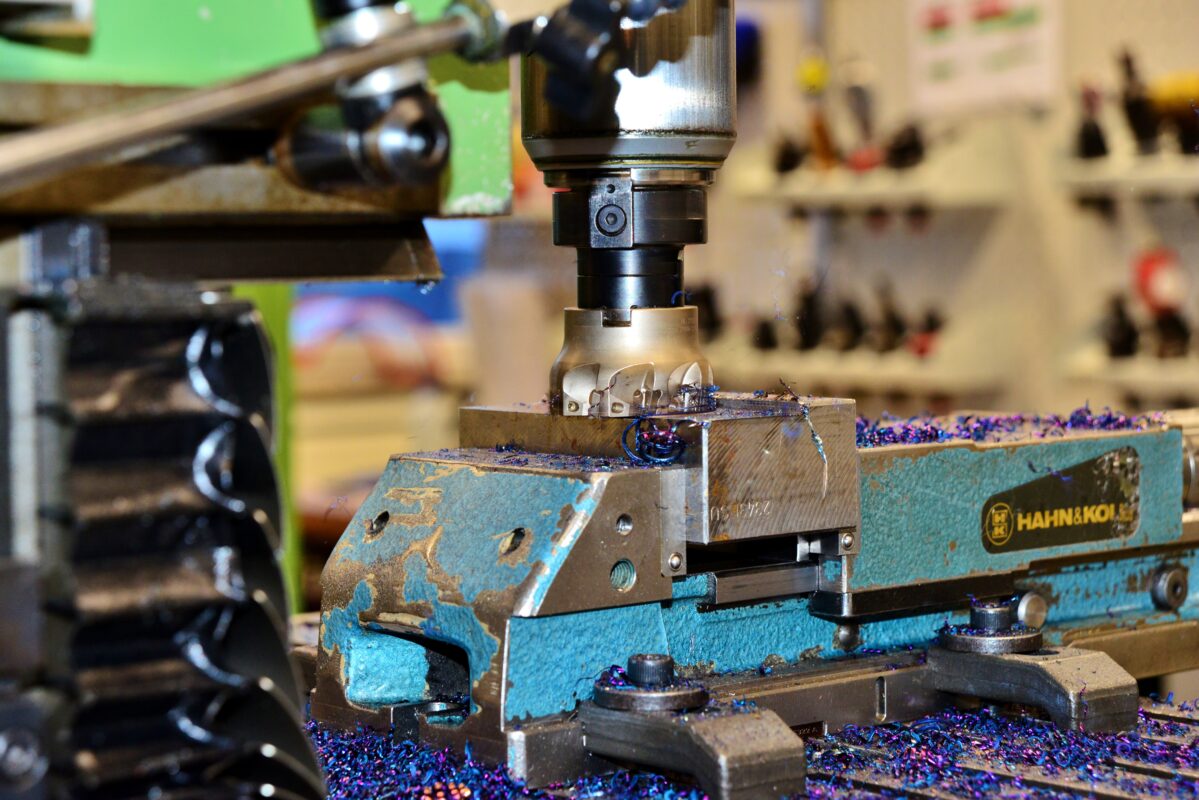

CNC milling machine

What is a CNC milling machine?

Among all types of CNC Machines, Computer Numerical Control or CNC milling machine is the most popular type. It let the computer control the axis rotation of the machine tool and the position of the working bench. This machine makes shapes of materials like metals, plastics, glasses, woods, etc. CNC milling machine can do different machining abilities such as drilling, turning, etc. This passage focuses on the CNC milling machines and their structure. The primary stages of a milling tool are,

- To draw a CAD design on AutoCAD or other famous software.

- The CAD Design into the CNC machine language.

- To manually set up the milling machine.

- Execution of the milling operation.

The milling machine is very much suitable to finalize a workpiece such as holes, threads, slots, etc. It makes an already machined workpiece into the desired model. CNC milling has not only advantages but also has a few considerations. While choosing a CNC machine, we must focus on what requirements we need to process our workpieces. There are various kinds of milling machines according to their strength and sizes on Amazon, Alibaba, etc. In later articles, we will review the milling machines specifications requirements for different purposes.

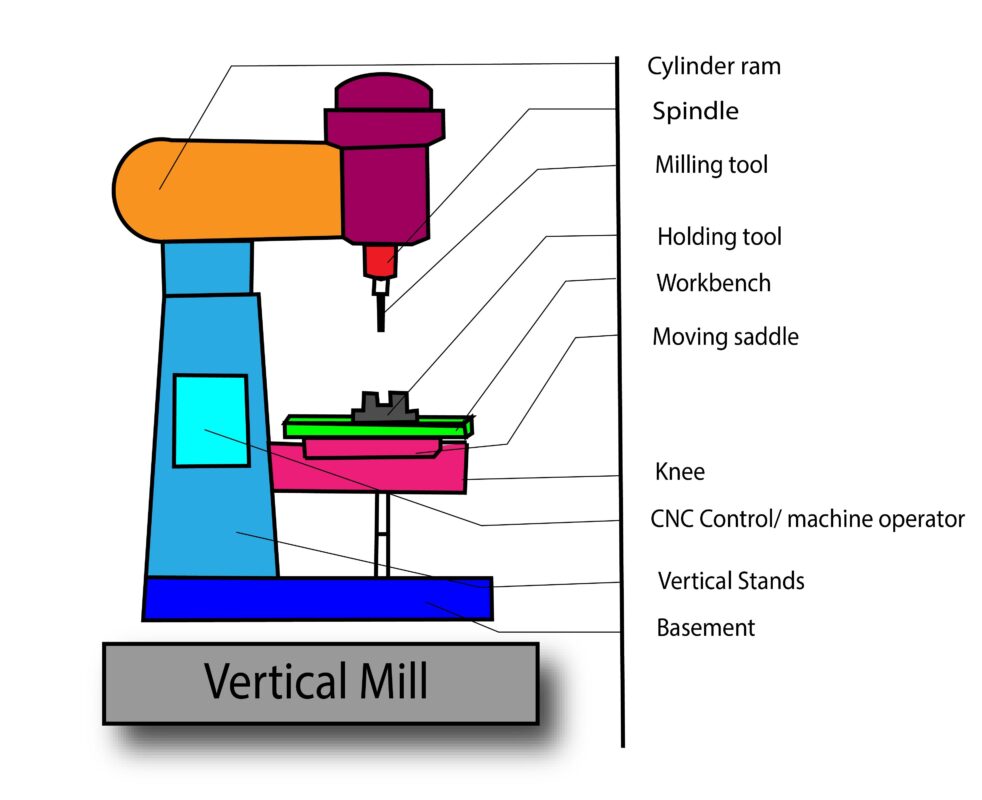

Structure of the CNC milling machine

There’re four types of CNC milling machine based on their axes and different product operations. Vertical mill, Bed Mill, Turret mill, Horizontal mill are the types based on their machine tool position.

This article focuses on the general structure of the several CNC machines types. So, let’s see a commonly used CNC milling machine.

The basic structure of a vertical CNC milling machine consists of several parts. They are: basement, vertical stand, cylinder ram on the top, spindle and milling tool is attached with the motor inside the piston, Knee located right above the basement, the moving saddle is right on the Knee, the working bench situated on the seat, the holding tool is right on top of the workbench.

There are other structures of the CNC milling machine based on their milling tool. But the purpose of them are all the same is to mill the workpiece.

CNC milling machine applications

The CNC milling machine has the tolerance range between +/- 0.001 to 0.005 inches. Consequently, It’s a very high precision machine. CNC milling machine makes a variety of product features and designs such as threads, chamfers, slots, pockets, etc. in the industry. The everyday milling machine operations are:

- Face milling: Face milling cutting operation refers to the axis of rotation which is perpendicular to the cutting tool.

- Plain milling: Plain milling cutting operation refers to the axis of rotation which is parallel to the cutting tool.

- Angular milling: Angular milling cutting operation refers to the axis of rotation which is at a specific angle with the cutting tool.

- Form milling: The parts such as curved surfaces, contours, etc. are operated in the form milling process. This process makes a formal shape of a surface.

- Others:

- Straddle milling: This milling process performs one single cut with two or more parallel surfaces.

- Gang milling: Gang milling simply refers to two or more cutting on the same machine arbour.

- Profile milling: This milling process creates a cut path on the vertical surface of the product.

- Gear cutting: This process especially cuts the gear threads.

- Others: Other machining processes such as drilling, turning, boring, reaming, tapping, etc. are also can be performed in this CNC milling machine.

Pros

- There’s no manual operation. It doesn’t need to turn on and off to change the position. It’s automated controlled by the computer.

- Productivity.

- High precision.

- The original product can be replicated to thousands without any defects.

- No need for labor costs.

- Using virtual software, educational training is also available.

- Many CNC machines can be operated by only one operator.

Cons

- The buying cost is too high.

- Operators must be well trained in mathematics and also in engineering.

Please See this YouTube video for the practical learning.

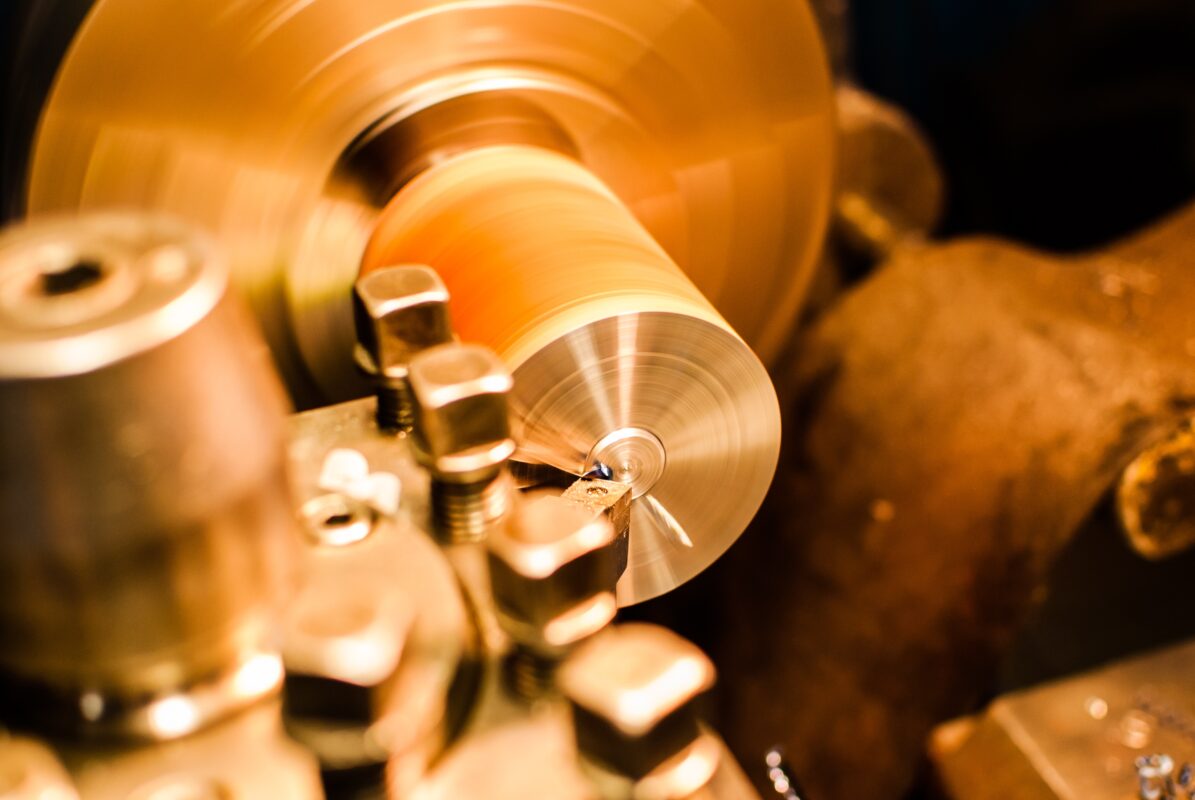

CNC lathe machine

What is a CNC lathe machine?

CNC Lathe machine has simply defined a workbench where we can clamp the workpiece with a rotation. The cutting tool can move on various axis to make multiple shapes. Typically, a simple lathe machine can run on X-axis and Z-axis. The other positions, such as Y-axis, sub-spindles, or different locations, are known as turning centers.

Likely the CNC milling machine, CNC lathe has also various kinds in type. They are horizontal, Vertical, slant bed, Flatbed, Standard, Multi-axis, swiss type, Multi-spindle, B-axis, etc. In this part, we will focus on horizontal CNC lathe type, because we very often use this one.

The cutting procedure can also follow four steps same as CNC milling. The only difference between them is the working principle. Besides the CNC lathe machine can be divided into five kinds based on the different axis depict. They are the following:

- 2-axis CNC Lathe: 2 linear axes used to perform Outer/ inner diameter and facing operations, tapping, and drilling at the center.

- 3-axis CNC Lathe: Including two linear axes, it has additional axes. We often call this axis as a C – axis. We use this machine in standard milling operations, tapping, and boring operations.

- 4-axis CNC Lathe: Here, the additional axis is Y-axis. It is beneficial for more complex operations.

- 5-axis CNC Lathe: These types have two different turrets where one turret has three axes, and the other has two axes.

- Six or more-axis CNC Lathe: This lathe may include; double C-axis lathes, double turret lathe, Upper Y-axis lathe, secondary spindle, etc.

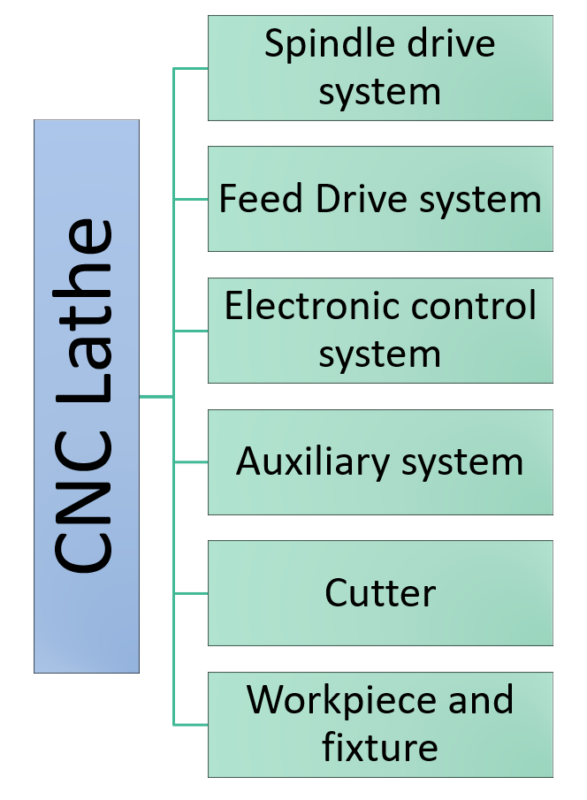

Structure of CNC Lathe machine

Comparing the other types of CNC lathe, the following are general components of the CNC lathe machine.

- Machine Bed: This is the main bed of a Lathe machine.

- Main Spindle: The main spindle is connected with the motor can rotate both clock and anticlockwise direction.

- Secondary Spindle: There are few categories where the machine has a secondary spindle for the complex machining process.

- Chuck: The stuck is just beside the spindle, which grabs the workpieces.

- Moving saddle: This part can move horizontally forward and backwards.

- Headstock: Headstock holds the main spindle.

- Tailstock: Supports the other part to support.

- Tool turret:Tool turret has four positions to hold the cutting tool, and it rotates to change the cutting tool.

CNC Lathe machine Application

CNC lathe machine usually is two types. Wood lathe, metal-metal lathe. The rotational speed of the wood lathe is higher than the metal lathe. The following are the primary application of the CNC lathe machine:

- Facing: Facing process is a process where we remove the materials to make a flat surface.

- Threading: The threading process is fundamental to make a bolt, screw, etc.

- Knurling: Knurling is a process to make a rough surface for a better grip.

- Drilling: Drilling is the process of cutting to make moles inside.

- The Boring: Boring is a single cutting process to make conical, cylindrical shapes.

- Reaming: We use reaming to finish drill holes.

- Taper Turning: We use this process to make tapper on the surface.

Pros

- High Precision

- Multi-coordinate linkage

- Easy access to programming.

- No need for labor

- Production capability is very high.

Cons

- The operator has to master the knowledge of mathematics and engineering.

- Buy cost is normally high.

- Maintenance is inconvenient.

Please See this YouTube video for the practical learning.

CNC Laser Engraver machine

What is a CNC Laser Engraver machine?

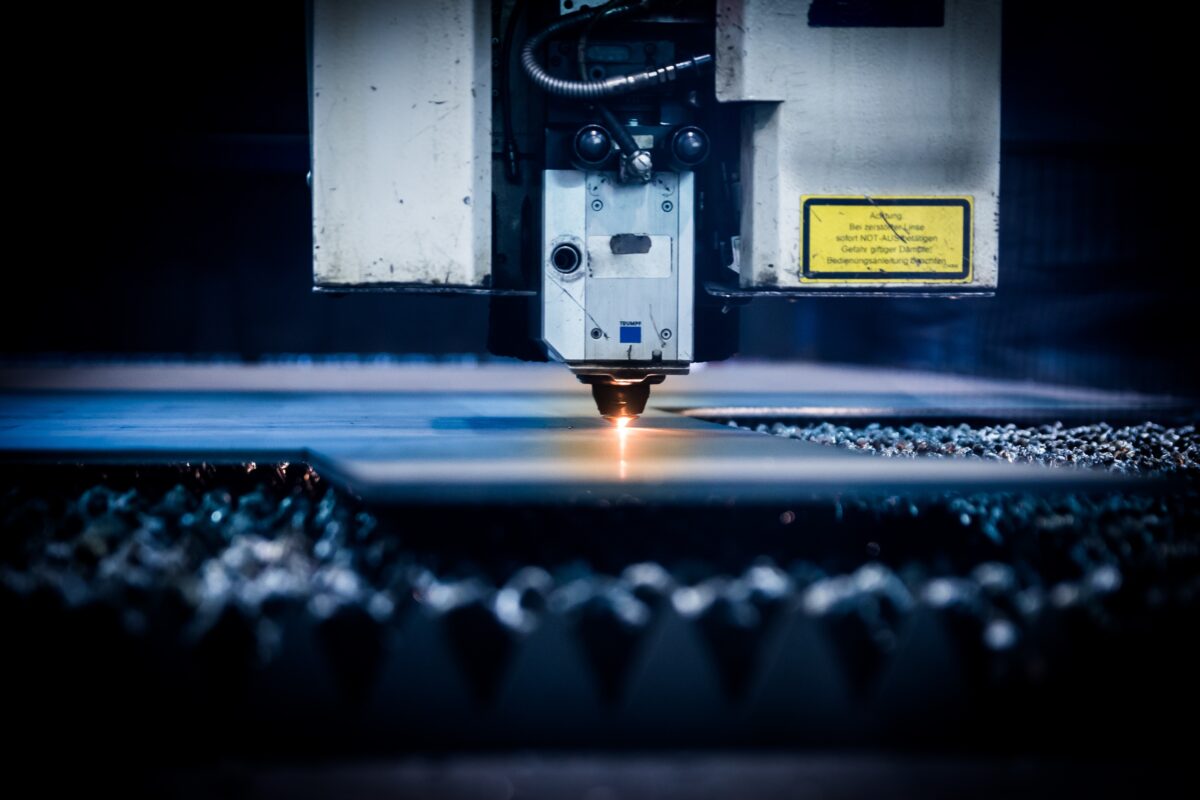

CNC Laser engraver machine is an exciting and artistic machine among all the CNC machines. This machine makes several artistic grips on the material surface. In ancient times, People engrave the metals using their hand. It took months to complete one surface’s design. When the CNC Laser cutter came, it became a few minutes of the task to achieve one surface. To learn an artistic grip is complicated and hard. But this laser engraver made that easy for us.

There are several kinds of laser engraver machine. This machine can engrave materials like wood, metal, plastics, acrylic, etc. Most of the factories use this machine. The most common use in the factory is to draw company name and production date on the product surface.

Structure of CNC Laser engraver machine

CNC laser cutting machine is almost similar to the router and plasma cutting machine. There are various kinds of laser machines. They are:

- Laser diodes: Laser diodes are typically 5 watts in power.

- C0₂ Gas lasers: This is the most common type in laser engraver machines. The layers contain CO₂ gas. We know they have high beam efficiency.

- Fibre Lasers: Fiber laser refers to solid-state lasers which generate a seed laser beam, and then by amplifying it in designed glass fibres. Fibre lasers are 100 times concentrated than CO₂ gas lasers. Most of the factories use this laser engraver.

- Crystal Lasers: Crystal layers are pretty much similar to the fibre laser.

In this section, we will elaborate on the general structure of a fibre laser engraver machine. Fibre laser engraver machine consists of the following components:

- A lifting handle modifies the position of the laser beam.

- Laser base is the holding point of the galvanometer

- The galvanometer is the base point.

- F-theta lens amplifies the concentration of the beam.

- The rotatory fixture holds and modifies the position of the workpiece.

- The marking plate is the base plate on which we place the product to get ready to engrave.

- Several switches control the laser beam operations.

CNC laser engraver machine applications

AA laser engraver machine is a widely used machine in every country. People need to save time and money. Many designers now design on the computer and then paste those on the desired material. The following are the leading application platform in which we use these laser engraver machines.

Artistic works: As we mentioned before, we use a laser engraver machine for artistic works. If we go to the showpiece shop, we will see some best examples of these kinds. These creative designs are done on bamboo, metals, woods, plastics, etc. People even sketch their photo on the wood frame. SO, this is an attractive application of this machine. Wood laser cutter, laser engraver for metal is different in specifications.

Industrial Uses: This Laser engraver machine is used in the factory to design their company names and dates of production. All the wood factories use this machine very often.

Pros

- Fast and beautiful machining plane. Dimensional works such as words, pictures can be machined on the materials.

- High precision.

- No need for labour.

- Saves times.

Cons

- Only 2 dimensional.

- Expensive to buy.

- Laser beams are harmful to human bodies, so we have to be careful while using it.

Please See this YouTube video for the practical learning.

CNC router machine

What is a CNC router machine?

CNC router machine is a piece of computer-controlled equipment that we use for cutting metals or woods. In the carpenter workshops, we can see this CNC machine. CNC router machine is very similar to the CNC milling machine. The difference between them is one of their axes is not mobile, and the other one can move along the axes.

In place of routing by hand, the computer controls the tool path operation by this routing machine. It helps the carpenter save time and make products in a day. There are some types of CNC routing machines such as the Industrial CNC router device, Mid-range CNC router device, Hobby CNC router device, Specially designed CNC router device.

Structure of the CNC router machine

The main structure of a CNC router machine consists of the following parts:

- Spindle: On the top of the device, there is a spindle attached to a strong motor that rotates in a clock or anti-clock direction called the rotating spindle.

- Geometry X-Axis rod: This is a fixed rod on the machine which moves forward and backwards. Besides, the spindle on it can move right and left according to the desired position from the operator’s design.

- Automated oil lubricant system: This is an automated system controlled by the operator from the computer. It moves along the Y-axis. It is an oil lubricant automated machine to carry the X-axis rod.

- CNC control system: CNC control system is a device where the computer converts the computer-aided design to the CNC machine language. It commands the machine to draw according to the design from the computer.

- Cutting tool: Cutting tools can be in various shapes. It depends on the types of drawing the operator wants to operate. There are different kinds such as ball nose, polycrystalline, PCB print circuit, bigger carbide router, etc.

CNC router machine applications

- Architectural millwork: Many houses foundation, roadside structures, rooftop, etc. are the architectural millwork performed by the CNC router device.

- This CNC router machine does cabinet making: Cabinet works at the carpenter workshops.

- Sign making: Ford, BMW, etc. a CNC router tool machines solid logos.

- Fabrication and cutting: CNC router also makes the desired shape on plastic or metal materials. It also cuts the foam for the packaging of products.

- Furniture making: This CNC router machine also machines chairs, tables, sofa designs, and structural design.

- General woodworking: hand tools, kitchen tools, etc. also machined by this machine.

- Engraving: Besides all those works, this CNC router machine can also perform some engraving machining process.

Pros

- High Accuracy

- Fast production

- Safe to operate

- Required tools are less

- No Human error

- Reliable

- Can be machined more complex designs

- Low maintenance

- Versatile

- Uniform designs

- It can be machined 24hours.

Cons

- Expensive

- The trained operator needs to operator

Please See this YouTube video for the practical learning.

CNC Plasma Cutting machine

What is a CNC Plasma Cutting machine?

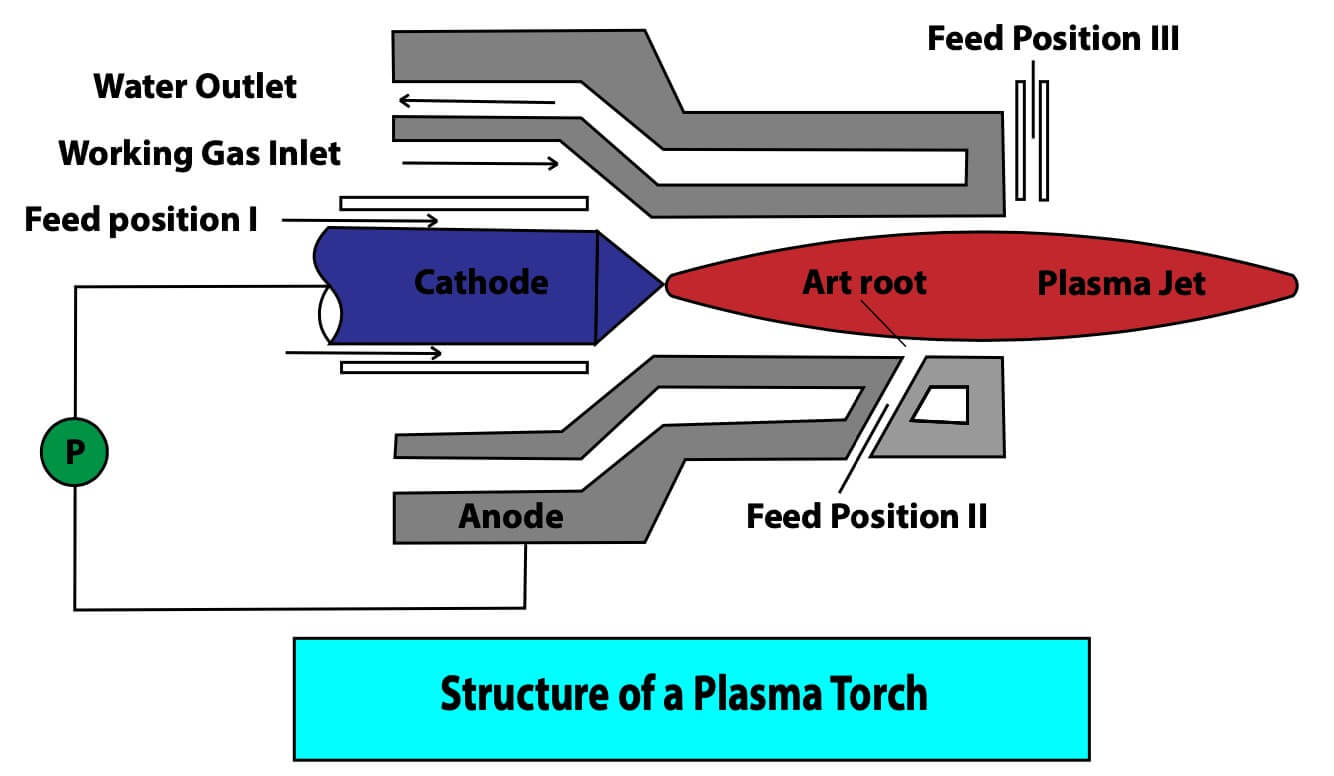

We use CNC Plasma cutting device in various machining purposes. Moreover, we also use this plasma cutter to cut sheet metal, metal plates, straps, bolts, pipes, etc. Besides, it can also make a gouging tool for weld joints or removing the defect. CNC plasma cutting is necessary for accuracy and good quality. A CNC plasma device contains a plasma torch and moves in a path operated by the computer.

Structure of Plasma cutting machine

The structure of a CNC plasma cutting machine is almost similar to the CNC cutting router. The only difference is the plasma torch. Let’s have a glance at the structure of the plasma torch. The main structure has:

- Working gas inlet path

- Three feeding position

- Anode and cathode diode

- Power source

- Plasma jet.

From the knowledge of physics, Plasma is one of them for fundamental elements in nature. The gas of ions can produce Plasma. Its penetration power is comparatively very high. So, the working gas is converted into a plasma jet in the CNC machine and then moves out from the machine cuts the metal into the desired shape.

CNC Plasma cutting machine Applications

CNC plasma cutting machine is widely used to cut metal smoothly. This machine can be used in Metal cabinet cutting, Metal sign making, metal tools making, anything which is a metal can be cut more accurately in plasma cutting machine.

Pros

- Wide cutting area

- Fast and efficient

- High accuracy

- Requires No Labor cost.

- Automated and easy to access.

Cons

- Difficult to cut more than 20mm of the plate. If its is requires higher power of plasma.

- Expensive machines.

Please See this YouTube video for the practical learning.

These 5 types of CNC machines are the commonly used computer-controlled machine in the world. There are few kinds of other CNC machines such as CNC press brake machine, CNC EDM machine, CNC waterjet plastic engraving machine, CNC stone engraving machine, CNC jewellery engraving machine, CNC swiss machine, CNC etching machine, etc. These are the subcategory of the five types we mentioned above. Based on different uses and specifications, these CNC machines differ from the standards. In this article, we tried to make a summary of each of the tools. Later on, we will elaborately discuss them, their working principle, configuration, and specifications. We will bring the best knowledge of the CNC machines. Stay with us and learn more.